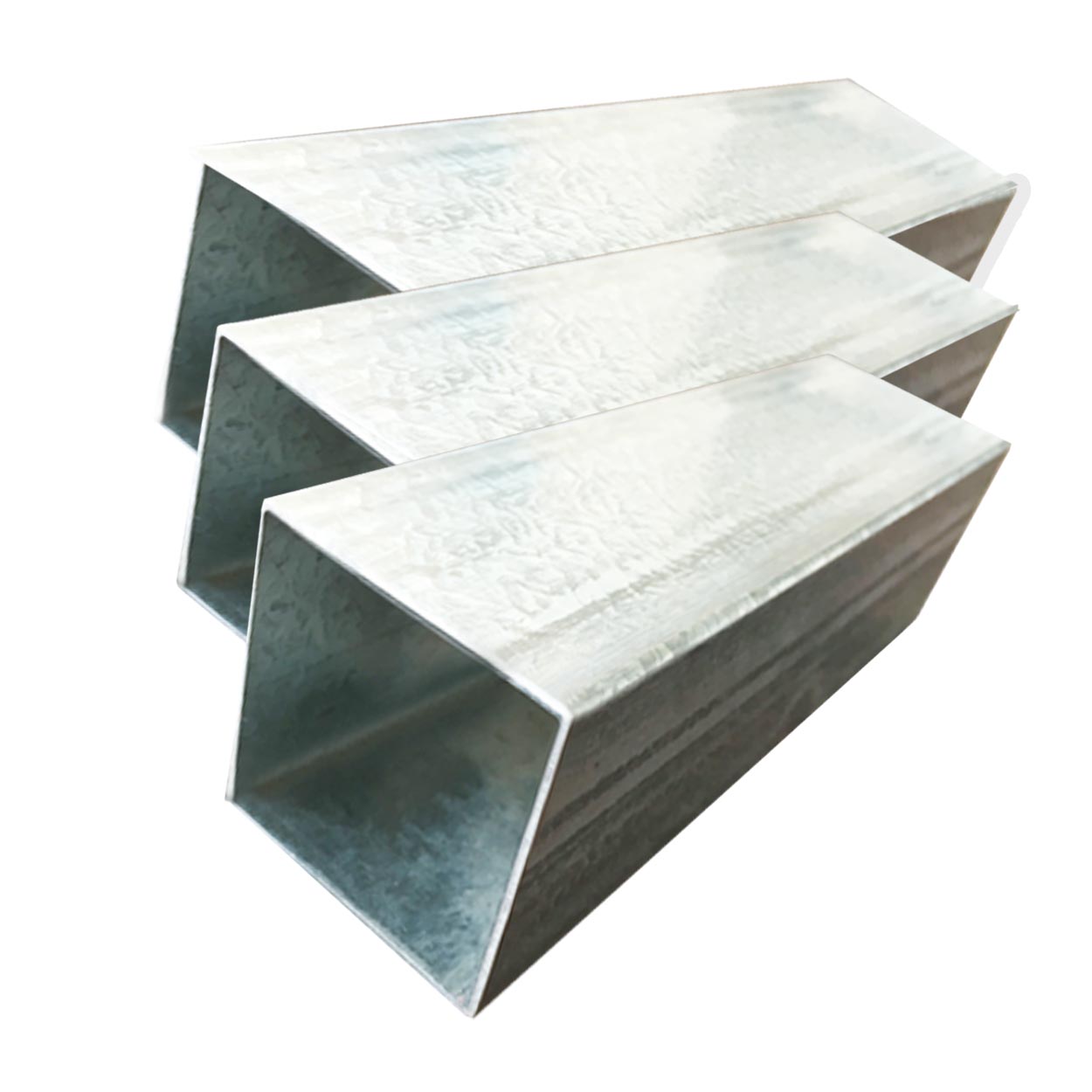

Galvanized Square Tubes

About Galvanized Square Tubes

Galvanized square tubing offers excellent structural strength and superior corrosion resistance from its zinc coating. Conforms to ASTM A500 Grade B standards. Ideal for outdoor frames, gates, and supports. In stock with custom cutting available.

Quick Facts

- Material: Galvanized Steel (A500 Grade B)

- ASTM Standard: A500

- Available Sizes: 5/8" to 1-1/2" square; 11 & 16 gauge walls

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

Galvanized square steel tubing is a carbon steel tube that has been hot-dipped in a protective zinc coating. This process provides a durable, abrasion-resistant barrier against rust and corrosion, making it ideal for outdoor and high-moisture environments. The uniform square shape offers excellent structural integrity and compression strength, simplifying fabrication for frames and supports. It combines the strength of steel with long-lasting environmental protection, reducing long-term maintenance needs.

Manufactured to meet ASTM A500 Grade B specifications, this tubing has a minimum yield strength of 46,000 PSI, suitable for load-bearing applications. Its smooth, consistent surface is ready for fabrication but can also be painted for aesthetic purposes. The combination of strength, weldability, and corrosion resistance makes galvanized square tube a practical choice for projects where durability against the elements is a primary requirement.

Technical Specifications

Mechanical Properties (A500 Grade B)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 58,000 | PSI |

| Yield Strength | 46,000 | PSI |

| Elongation | 23 | % |

Applicable Standards

- ASTM A500: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes.

Common Applications

- Fencing & Gates: Gate frames, fence posts, and railings due to superior weather resistance.

- Construction: Support columns, structural framing, and scaffolding where moisture is present.

- Agriculture: Livestock enclosures, greenhouse frames, and equipment support structures.

- Trailers: Utility trailer frames, tongues, and cross-members for durability.

- Outdoor Signage: Sign posts and support frames that resist rust.

- Architectural: Decorative handrails, pergolas, and outdoor canopies.

- Marine: Dock supports and boat trailer components where rust is a concern.

- Playground Equipment: Frames for swingsets and climbing structures requiring longevity.

Working with Galvanized Square Tubes

Machining

Galvanized steel tubing is machinable, but the zinc coating can clog cutting tools. Use slower speeds and sharp tooling. Grinding or filing the weld zone before machining is recommended for better tool life.

Welding

Excellent weldability using common methods like MIG and Stick. Welding burns off the protective zinc coating at the heat-affected zone, creating hazardous fumes. Proper ventilation is critical. The welded area must be cleaned and re-coated with a zinc-rich paint to restore corrosion resistance.

Finishing

The galvanized finish is the primary surface treatment for corrosion protection. It can be painted, but the surface must be properly cleaned and primed with a wash primer or etch primer to ensure adhesion.

Related Products

Frequently Asked Questions

Q: What is the difference between galvanized and regular steel tubing?

A: Galvanized tubing is coated in a layer of zinc, which provides excellent protection against rust. Regular (black) steel tubing has a mill scale surface and will rust quickly if left unprotected outdoors. Galvanizing significantly extends the service life in wet or humid environments.

Q: Can I weld galvanized square tube?

A: Yes, it is highly weldable. However, welding vaporizes the zinc coating, producing hazardous fumes that require proper ventilation and respiratory protection. The welded area will need to be re-coated with a cold galvanizing spray to restore rust protection.

Q: What does ASTM A500 Grade B mean for this tube?

A: ASTM A500 is the standard for cold-formed structural steel tubing. Grade B specifies minimum mechanical properties, including a yield strength of 46,000 PSI and a tensile strength of 58,000 PSI, ensuring it is suitable for structural applications like frames and supports.

Stock & Custom Sizes

Available sizes: 5/8" to 1-1/2" square. Wall thicknesses include 16 gauge (0.060") and 11 gauge (0.120"). Standard lengths: 24 ft. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed Galvanized Square Tubes? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 0.450 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 0.592 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 0.750 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 0.958 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 1.208 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 1.881 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 3.000 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |