Steel

About Steel

Steel is an iron-carbon alloy valued for its exceptional strength, durability, and versatility. Common grades meet ASTM standards like A36 and A108, serving applications from structural framing to precision machinery. Bobco Metals is a Los Angeles steel supplier with in-stock material and custom cutting.

Quick Facts

- Material: Carbon & Alloy Steel

- ASTM Standard: A36, A108, A500, A53

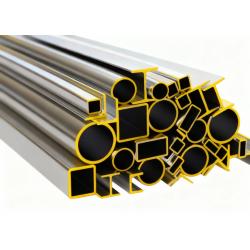

- Available Shapes: Bar, plate, sheet, tube, pipe, angle, channel

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

Steel is one of the most fundamental materials in modern industry, prized for its high tensile strength, impact resistance, and cost-effectiveness. The material is primarily an alloy of iron and carbon, with the carbon content determining its hardness and strength. Steel is broadly categorized into carbon steels and alloy steels. Carbon steels, such as 1018, are defined by their carbon content, while alloy steels, like 4140, incorporate other elements such as manganese, chromium, or molybdenum to enhance properties like hardness, toughness, and corrosion resistance. The manufacturing process, either hot-rolled or cold-rolled, also significantly impacts the material's final surface finish and dimensional tolerances.

The versatility of steel is evident in its vast range of forms and applications. Hot-rolled structural grades like ASTM A36 are the backbone of construction, used for I-beams, channels, and angles. For applications requiring a better surface finish and tighter tolerances, cold-rolled steel like 1018 is used for machined parts, shafts, and fasteners. High-strength alloy steels are specified for demanding mechanical components including gears, axles, and tooling. At Bobco Metals, steel is available in numerous profiles, including flat bar, round bar, sheet, plate, pipe, and tubing to meet diverse fabrication and manufacturing requirements.

Technical Specifications

Mechanical & Chemical Properties

Mechanical properties and chemical composition vary significantly by steel grade. Please refer to specific grade pages (e.g., A36, 1018, 4140) for detailed specifications or view the grade comparison table.

Applicable Standards

- ASTM A36: Standard Specification for Carbon Structural Steel

- ASTM A108: Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished

- ASTM A500: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing

- ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

- ASTM A572: Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel

Common Applications

- Construction: I-beams, C-channels, and angle iron for building frames due to A36's strength and weldability.

- General Fabrication: Brackets, base plates, and supports from hot rolled flat bar and sheet for its cost-effectiveness.

- Machining: Shafts, pins, and housings from 1018 cold rolled round bar for its tight tolerances and good machinability.

- Automotive: Gears, axles, and crankshafts from 4140 alloy steel for its high tensile strength and toughness after heat treatment.

- Infrastructure: Handrails, bollards, and fencing from A53 black pipe for its durability and structural integrity.

- Manufacturing: Jigs, fixtures, and machine frames from A500 structural tubing for its high strength-to-weight ratio.

- Agriculture: Equipment frames and implement components from A572 steel for its higher strength over A36.

- Energy: Pipeline components and structural supports in processing facilities for its robustness and reliability.

Working with Steel

Machining

Machinability varies by grade. Low-carbon steels like 1018 are easily machined with standard tooling. Higher-carbon and alloy steels, such as 1045 and 4140, are tougher and require slower speeds and more robust tooling to achieve a good finish and prevent work hardening.

Welding

Most common carbon steels (A36, 1018, A500) have excellent weldability using standard methods like MIG and TIG. Alloy steels may require pre-heating and post-weld heat treatment (PWHT) to prevent cracking and maintain the integrity of the heat-affected zone.

Finishing

Carbon steel is susceptible to rust and typically requires a protective finish for most applications. Common options include painting, powder coating, or hot-dip galvanizing for superior corrosion resistance in exterior or harsh environments. An oil finish is often applied for temporary protection.

Grades Comparison

| Grade | Tensile (PSI) | Yield (PSI) | Best For |

|---|---|---|---|

| A36 | 58,000-80,000 | 36,000 | Structural frames, plates, general fabrication |

| 1018 | 63,800 | 53,700 | Machined parts, shafts, pins, brackets |

| 4140 | 95,000 | 60,000 | High-stress gears, axles, bolts, tooling |

| A500-B | 58,000 | 46,000 | Framework, roll cages, structural supports |

Frequently Asked Questions

Q: What is the difference between hot rolled and cold rolled steel?

A: Hot rolled steel is formed at high temperatures, resulting in a rougher, scaled surface and looser dimensional tolerances. Cold rolled steel is processed further at room temperature, which produces a smooth, more refined surface finish and precise dimensions.

Q: Which steel grade is best for welding?

A: Low-carbon steels like ASTM A36 and 1018 are excellent for welding and do not typically require special procedures. Higher carbon and alloy steels can be welded, but often require preheating and post-weld heat treatment to avoid brittleness in the weld zone.

Q: Does carbon steel rust?

A: Yes, all carbon and alloy steels contain iron and will rust if exposed to moisture and oxygen. For corrosion protection, the material must be protected with a coating such as paint, powder-coat, galvanizing, or a layer of oil.

Stock & Custom Sizes

Available in a wide range of shapes including round, flat, and square bar, plate, sheet, pipe, tubing, angle, and channel. Stocked in standard mill lengths and dimensions. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed Steel? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert