- Category

- 3003 Aluminum 9

- 5052 Aluminum 0

- 6061 Aluminum 84

- 6063 Aluminum 22

Aluminum

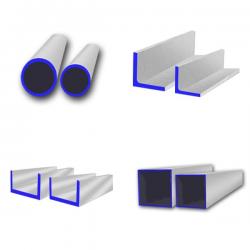

A comprehensive selection of aluminum alloys, including 6061, 3003, 5052, and 7075. Available in sheet, plate, bar, tube, and structural shapes for immediate pickup in Los Angeles.

About Aluminum

Aluminum is a lightweight, strong, and highly corrosion-resistant metal used across industries from aerospace to construction. Common alloys meet standards like ASTM B209 and B221. An excellent choice for structural frames, panels, and machined parts. In-stock at our Los Angeles warehouse.

Quick Facts

- Material: Aluminum Alloys (6061, 3003, 5052, 7075)

- ASTM Standard: B209, B211, B221, B241, B308

- Temper/Condition: T6, H14, H32

- Available Sizes: Various sheet, plate, bar, and tube sizes

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

Aluminum is a non-ferrous metal prized for its low density—approximately one-third that of steel—and excellent strength-to-weight ratio. This inherent lightness, combined with its high thermal and electrical conductivity, makes it a versatile material for countless applications. A key characteristic is the formation of a passive oxide layer on its surface, which provides exceptional natural corrosion resistance. Specific properties are achieved by adding alloying elements like magnesium, silicon, and zinc. This creates distinct grades, from the highly formable 3003 alloy used in sheet metal work to the high-strength 7075 alloy required for aerospace components.

The workability of aluminum allows it to be easily machined, formed, and fabricated into complex shapes, including sheet, plate, bar, and structural extrusions. Its use is widespread in transportation for automotive bodies and aircraft fuselages, in construction for window frames and curtain walls, and in consumer goods for electronics enclosures. The 5xxx and 6xxx series alloys are particularly well-suited for welding. As one of the most recycled industrial materials, aluminum is a sustainable choice for modern manufacturing and fabrication projects, available for same-day pickup from our Los Angeles facility.

Technical Specifications

⚠️ Reference Data Only: Values shown are typical industry standards and may vary by

manufacturer, lot, and heat treatment. For critical applications, please contact us to verify

specifications or request a Mill Test Report (MTR).

Mechanical and chemical properties are grade-specific. Please refer to the 'Grades' tab for a comparison of common alloys or navigate to a specific grade page for detailed data tables.

Applicable Standards

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B211: Standard Specification for Aluminum and Aluminum-Alloy Bar, Rod, and Wire

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B308: Standard Specification for Aluminum-Alloy 6061-T6 Standard Structural Profiles

- ASTM B241: Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

Common Applications

- Aerospace: Aircraft fuselages, wing components, and structural fittings - for its high strength-to-weight ratio (7075, 2024).

- Marine: Boat hulls, masts, and hardware - for superior corrosion resistance in saltwater environments (5052, 5083).

- Automotive: Body panels, engine blocks, and chassis components - to reduce vehicle weight and improve fuel efficiency.

- Construction: Window frames, curtain walls, and roofing - due to its durability and low maintenance (6063).

- Electronics: Enclosures, heat sinks, and chassis - for its excellent thermal conductivity and non-magnetic properties.

- Food & Beverage: Cookware, containers, and foil - because it is non-toxic, corrosion-resistant, and an effective barrier.

- Signage & Architectural Panels: Storefronts and decorative elements - for its formability and ability to be anodized (3003).

- Machined Parts: Jigs, fixtures, and general components - for its excellent machinability and stability (6061).

Working with Aluminum

Machining

Aluminum generally offers excellent machinability. Grades like 6061 and 7075 produce clean, crisp chips and smooth finishes. Softer alloys can be 'gummy,' requiring sharp tooling and proper lubrication. High-speed steel (HSS) or carbide tools are effective for cutting, drilling, and milling operations.

Welding

Weldability varies significantly by grade. The 5xxx (e.g., 5052) and 6xxx (e.g., 6061) series alloys are readily weldable using TIG (GTAW) and MIG (GMAW) processes. High-strength 2xxx and 7xxx series alloys are generally not recommended for welding due to cracking susceptibility and loss of mechanical properties.

Finishing

Aluminum accepts a wide range of finishes. Anodizing is a common electrochemical process that increases surface hardness and corrosion resistance while allowing for various colors. It can also be painted, powder-coated, or polished to a brilliant, mirror-like finish.

Grades Comparison

| Grade | Tensile (PSI) | Yield (PSI) | Best For |

|---|---|---|---|

| 6061-T6 | 45,000 | 40,000 | General purpose structural use, machining |

| 3003-H14 | 22,000 | 21,000 | Excellent formability, sheet metal work |

| 5052-H32 | 33,000 | 28,000 | Marine applications, good weldability |

| 7075-T6 | 83,000 | 73,000 | High-stress aerospace components |

| 2024-T3 | 70,000 | 50,000 | High fatigue resistance, aircraft structures |

| 6063-T5 | 27,000 | 21,000 | Architectural extrusions, smooth finish |

Frequently Asked Questions

Q: What is the difference between aluminum sheet and plate?

A: The primary difference is thickness. Material under 0.250"" is typically considered aluminum sheet, while material 0.250"" and thicker is classified as aluminum plate.

Q: Which aluminum grade is best for welding?

A: Alloys in the 5xxx series (like 5052) and 6xxx series (like 6061) offer excellent weldability using common TIG or MIG methods. Grades in the 2xxx and 7xxx series are generally not recommended for welding.

Q: Can aluminum be used outdoors?

A: Yes, aluminum's natural oxide layer provides excellent corrosion resistance, making it ideal for outdoor applications. For marine or harsh environments, grades like 5052 are preferred. Anodizing can further enhance this protection.

Stock & Custom Sizes

Available in a wide range of standard mill sizes. Sheet and plate are stocked in thicknesses from 0.020"" to over 1"", with standard 4x8 ft and 4x10 ft dimensions. Bar, tube, and structural shapes are available in various diameters and profiles with standard 12 ft or 20 ft lengths. Custom size available.

Same-day cutting and Los Angeles pickup available.

View ProductsNeed Aluminum? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert