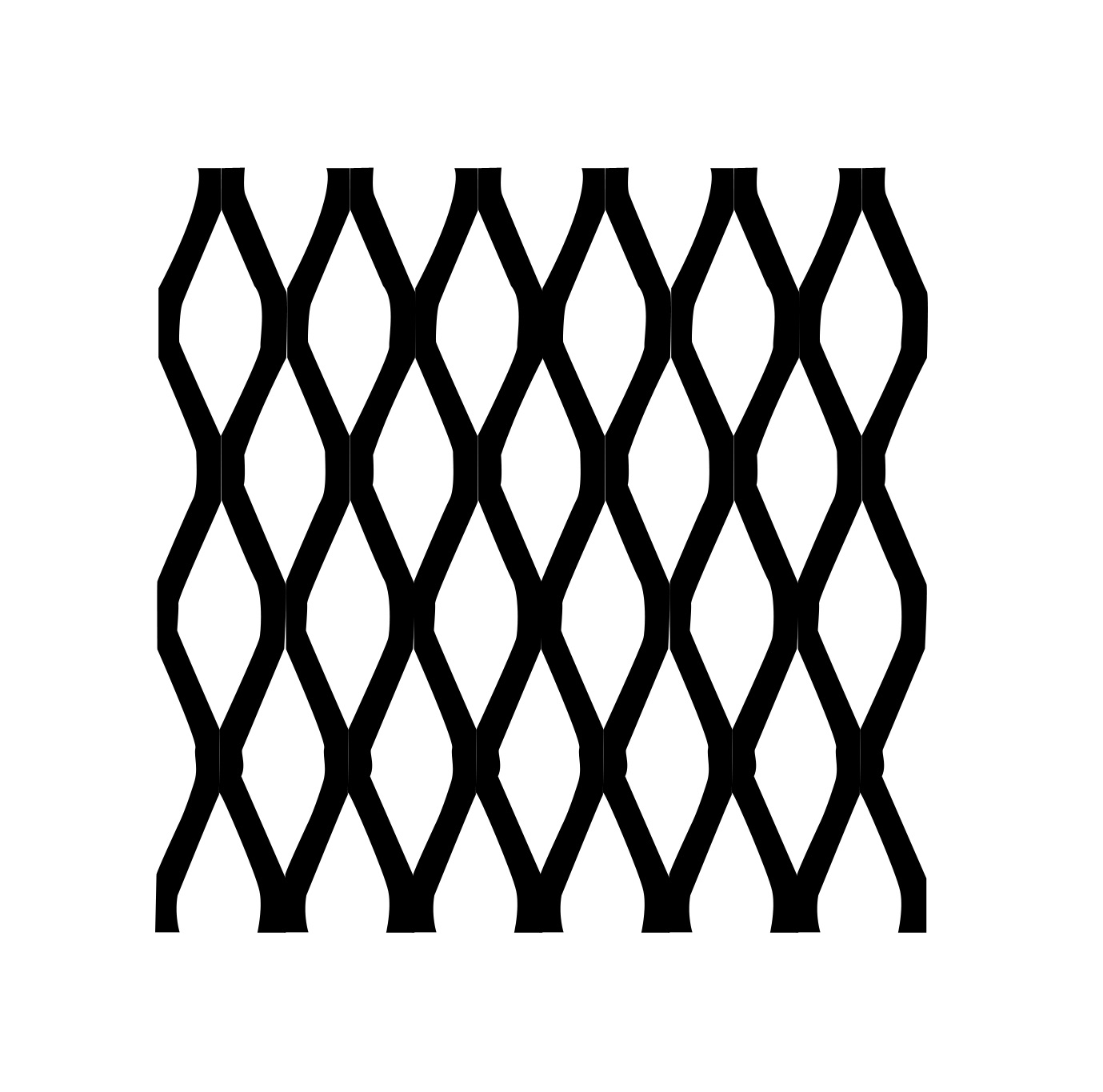

Hot Rolled Expanded Metal

About Hot Rolled Expanded Metal

Hot rolled flattened expanded metal provides an excellent strength-to-weight ratio, traction, and airflow. Made from weldable A36-grade steel. Ideal for industrial walkways, ramps, and security screens. In stock in Los Angeles with custom cutting available.

Quick Facts

- Material: Hot Rolled Carbon Steel (A36 equivalent)

- ASTM Standard: Base material typically conforms to A36

- Style: Flattened

- Available Sizes: Mesh sizes .50" & .75"; Gauges #9, #13, #16

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

Hot rolled expanded metal is produced by slitting and stretching a single steel sheet into a continuous diamond-pattern mesh with no welds or joints. This process creates a rigid, high-strength panel with a greater strength-to-weight ratio than solid plate. This product is flattened by passing it through cold rolls, resulting in a smooth, uniform surface that is easy to clean and provides a consistent thickness, unlike standard raised expanded metal.

The use of a hot rolled steel base provides good formability and excellent weldability, making it easy to fabricate. The inherent strength of its A36-equivalent chemistry ensures reliability for structural applications like catwalks and platforms. The open diamond pattern allows for the passage of light, air, and fluids, while providing a secure, non-slip surface, making it a versatile material for industrial, architectural, and transportation-related projects where durability and performance are required.

Technical Specifications

Mechanical Properties (Typical for A36 Base Material)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 58,000 - 80,000 | PSI |

| Yield Strength | 36,000 | PSI |

| Elongation | 20 | % |

| Hardness | 119 - 162 | HB |

Applicable Standards

- ASTM A36: Standard Specification for Carbon Structural Steel (for base material)

Common Applications

- Industrial Flooring: Walkways, catwalks, and mezzanines - High strength-to-weight ratio and open design for drainage.

- Transportation: Trailer ramps, utility trailer beds, and running boards - Excellent traction and durability.

- Security & Safety: Window guards, security fencing, and machine guards - Strong barrier that allows for visibility and airflow.

- Architectural: Building façades, sunscreens, and decorative infill panels - Modern aesthetic with functional benefits.

- Filtration: Grilles, vents, and heavy-duty filter supports - Allows passage of air or fluids while blocking debris.

- Construction: Stair treads, trench covers, and non-structural platforms.

- Agriculture: Livestock flooring, enclosure panels, and equipment platforms - Durable and easy to clean.

Working with Hot Rolled Expanded Metal

Machining

Expanded metal is typically not machined but can be drilled or punched. Due to the open pattern, use firm clamping to prevent vibration. Slower speeds and sharp tooling are recommended for clean cuts.

Welding

Excellent weldability. Can be joined using common methods like SMAW (Stick), GMAW (MIG), and GTAW (TIG) on the A36 base material. Preheating is not typically required for the thicknesses this material is available in.

Finishing

The hot rolled surface is suitable for painting, powder coating, or hot-dip galvanizing for enhanced corrosion resistance. Surface preparation like sandblasting or wire brushing is recommended prior to coating for best adhesion.

Related Products

Frequently Asked Questions

Q: What does ".75 #9" mean for expanded metal?

A: The ".75" refers to the nominal short way of the diamond (SWD) opening, which is 3/4 inch. The "#9" refers to the thickness of the metal strand, which is approximately 0.150 inches. A lower gauge number indicates a thicker, heavier-duty sheet.

Q: What is the difference between flattened and standard expanded metal?

A: Standard (or raised) expanded metal has angled strands that create a textured, high-traction surface. Flattened expanded metal is cold-rolled after expansion, creating a smooth, flat surface that is easier to clean and provides a more uniform thickness.

Q: Is hot rolled expanded metal suitable for outdoor use?

A: Uncoated hot rolled steel will rust when exposed to the elements. For outdoor applications, it must be protected with a suitable finish such as paint, powder coating, or hot-dip galvanizing to prevent corrosion.

Stock & Custom Sizes

Available mesh sizes: 0.50", 0.75". Gauges: #9, #13, #16. Standard sheets: 4×8 ft. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed Hot Rolled Expanded Metal? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert