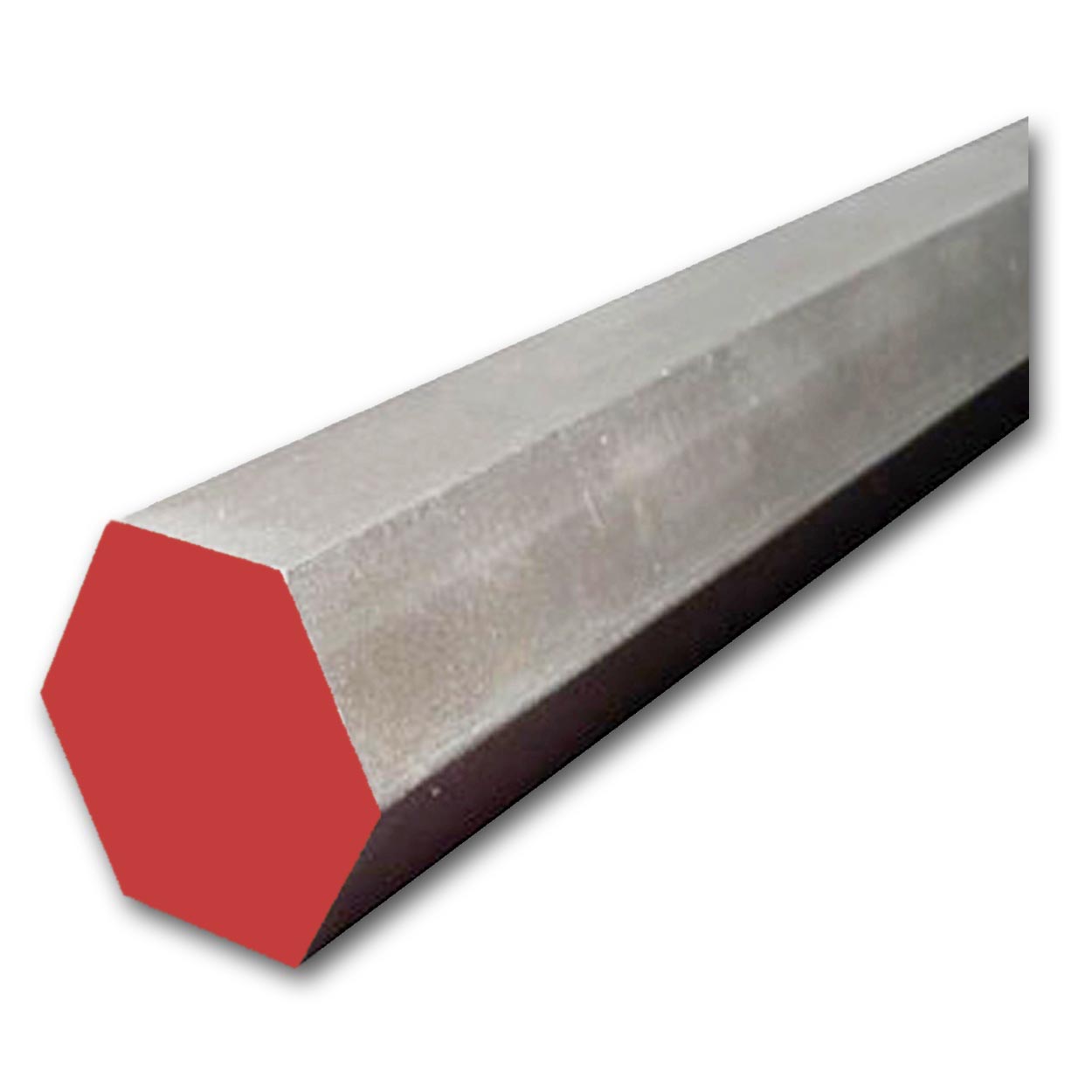

Cold Rolled Hexagons

About Cold Rolled Hexagons

1018 cold rolled hexagon bar offers a smooth finish, tight dimensional tolerances, and 63,800 PSI tensile strength. Meets ASTM A108 specifications. Ideal for fasteners, shafts, and machined components. In stock for Los Angeles pickup.

Quick Facts

- Material: 1018 Cold Rolled Steel

- ASTM Standard: A108

- Temper/Condition: Cold Finished

- Available Sizes: 3/16" to 1" hex

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

Cold rolled 1018 steel hexagon bar is produced through cold drawing, a process that improves its physical properties over hot rolled alternatives. This method results in a smooth, scale-free surface finish, tighter dimensional accuracy, and increased tensile and yield strength. Its low carbon content provides a balance of toughness, strength, and ductility. This material is well-suited for applications that require a superior surface finish and consistent dimensions direct from the mill, minimizing the need for secondary processing.

The key benefits of 1018 cold rolled hex bar include its excellent machinability and weldability. It can be easily fabricated using conventional methods and is receptive to case hardening treatments like carburizing for increased surface wear resistance. The hexagonal shape is specifically designed for creating fasteners like nuts and bolts, and for components that require positive gripping surfaces, such as custom tool shafts, hydraulic fittings, and machinery axles where precise geometry is a critical design requirement.

Technical Specifications

Mechanical Properties

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 63,800 | PSI |

| Yield Strength | 53,700 | PSI |

| Elongation | 15 | % |

| Hardness | 126 | HB |

Applicable Standards

- ASTM A108: Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished

Common Applications

- Fasteners & Industrial Hardware: Nuts, bolts, and threaded rods - Hex shape allows for easy tightening with standard tools.

- Machinery & Equipment: Spindles, shafts, and axles - Good strength and machinability for rotating components.

- Automotive: Pins, dowels, and small motor shafts - Tight tolerances for precise fitment in assemblies.

- Hydraulics & Pneumatics: Custom fittings and connectors - Excellent machinability for threading and sealing surfaces.

- Tooling & Fixtures: Handles, levers, and standoffs - Provides a durable gripping surface and structural support.

- Architectural & Decorative: Brackets and decorative hardware - Smooth finish is suitable for aesthetic applications.

- General Fabrication: Mounts and support components - Easily welded and machined into custom parts.

Working with Cold Rolled Hexagons

Machining

1018 steel has excellent machinability, rated at 70% compared to 1212 steel. It produces clean finishes when turned, milled, or drilled and is suitable for high-speed automated machining operations. The cold drawing process provides a consistent diameter that reduces setup time.

Welding

Due to its low carbon content, 1018 steel is readily weldable using all standard techniques, including MIG, TIG, and stick welding. Preheating and post-heating are generally not required for thinner sections, but may be beneficial for larger dimensions to prevent stress cracking.

Finishing

The smooth, clean surface of cold rolled 1018 is an excellent base for various finishes, including painting, powder coating, and plating (zinc, chrome, nickel). It is also well-suited for case hardening (carburizing) to create a hard, wear-resistant outer layer while maintaining a ductile core.

Related Products

Frequently Asked Questions

Q: What is the difference between 1018 cold rolled and hot rolled steel?

A: Cold rolled 1018 is processed further than hot rolled. It's drawn through dies at room temperature, giving it a smoother surface finish, tighter dimensional tolerances (+/- 0.002"), and higher tensile strength (approx. 64,000 PSI). Hot rolled steel has a rough, scaly finish and lower strength.

Q: Can 1018 steel be hardened?

A: 1018 steel has low carbon content, so it cannot be effectively through-hardened with heat treatment. However, it is an excellent candidate for case hardening processes like carburizing, which creates a very hard, wear-resistant surface layer while the core remains soft and ductile.

Q: Is 1018 hex bar suitable for making high-strength bolts?

A: 1018 is ideal for general-purpose bolts and fasteners (e.g., Grade 2). For certified high-strength structural bolts (like Grade 5 or 8), a medium-carbon or alloy steel that can be heat-treated, such as 1045 or 4140, is required.

Stock & Custom Sizes

Available sizes: 3/16" to 1" hex. Standard lengths: 12 ft. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed Cold Rolled Hexagons? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 0.104 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |