6063 Aluminum

About 6063 Aluminum

6063 aluminum is an architectural alloy with excellent corrosion resistance, a smooth surface finish, and good formability. Conforms to ASTM B308/B221 standards. Ideal for window frames, trim, and decorative parts. Los Angeles stock with custom cutting.

Quick Facts

- Material: 6063-T5 Aluminum

- ASTM Standard: B221, B308, B241

- Temper: T5 (Cooled from an elevated temperature shaping process and artificially aged)

- Available Sizes: Angles from 3/4" to 1-1/2"; other shapes available

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

6063 aluminum, often called the "architectural alloy," is a medium-strength material known for its exceptional surface finish and high resistance to corrosion. Its primary alloying elements are magnesium and silicon, which allow it to be easily extruded into complex shapes with smooth surfaces. While not as strong as 6061, its aesthetic qualities make it a top choice for applications where appearance is critical. The T5 temper provides a good balance of strength and ductility for most common uses.

A key advantage of 6063 aluminum is its excellent response to anodizing, which can produce a wide range of clear, color, and hardcoat finishes for decorative and protective purposes. The material is also easily weldable using common methods like MIG and TIG, although the heat-affected zone will experience a reduction in strength. Its combination of extrudability, finish, and corrosion resistance makes it a more suitable and cost-effective choice than 6061 for non-structural architectural and decorative applications.

Technical Specifications

Mechanical Properties (6063-T5)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 27,000 | PSI |

| Yield Strength | 21,000 | PSI |

| Elongation | 12 | % |

| Hardness | 60 | HB |

Applicable Standards

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- ASTM B308: Standard Specification for Aluminum-Alloy Standard Structural Profiles.

- ASTM B241: Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube.

- ASTM B210: Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes.

Common Applications

- Architectural & Construction: Window frames, door frames, and storefronts - for its extrudability and superior finish.

- Furniture Manufacturing: Table legs, chair frames, and outdoor furniture - for its light weight and smooth surface.

- Electronics: Heatsinks and electronic enclosures - due to good thermal conductivity and ability to be extruded into complex profiles.

- Piping Systems: Irrigation pipes and compressed air lines - for its corrosion resistance and smooth interior walls.

- Automotive: Decorative trim, roof racks, and running boards - for its appearance and light weight.

- Display & Signage: Sign frames and exhibit structures - because it is easy to fabricate and has a clean look.

- Railings & Fencing: Handrails, balustrades, and fence posts - for safety and aesthetic applications.

Working with 6063 Aluminum

Machining

6063 aluminum has fair to good machinability. It produces continuous, gummy chips. Using high speeds, heavy feeds, and sharp tooling with adequate lubrication is recommended for the best surface finish. It is softer than 6061, which can make achieving tight tolerances more challenging.

Welding

This alloy is readily weldable using common techniques like TIG (GTAW) and MIG (GMAW). 4043 or 5356 filler wire is typically used. Welding will reduce the strength in the heat-affected zone (HAZ) back to an annealed state; post-weld heat treatment is not typically performed.

Finishing

6063 is the premier choice for finishing, especially anodizing. It produces a consistent and aesthetically pleasing anodized surface. It can also be polished, brushed, powder-coated, or painted to achieve a wide variety of decorative and protective finishes.

Related Aluminum Grades

Frequently Asked Questions

Q: What is the difference between 6063 and 6061 aluminum?

A: 6061 aluminum has significantly higher strength (45,000 PSI tensile), making it ideal for structural applications. 6063 has lower strength (27,000 PSI tensile) but offers a much better surface finish, is easier to extrude into complex shapes, and provides a superior result when anodized.

Q: Is 6063 aluminum good for outdoor use?

A: Yes, 6063 has excellent resistance to atmospheric corrosion, making it a great choice for outdoor applications like window frames, railings, and outdoor furniture. For marine or saltwater environments, 5052 aluminum may be a more suitable option.

Q: Can I bend 6063 aluminum tube?

A: Yes, 6063 in the T5 temper has good formability and can be bent, though care must be taken to avoid cracking. Using proper tooling, a large bend radius, and potentially annealing the material can improve results for complex bends. For applications requiring extreme formability, an alloy like 3003 might be considered.

Stock & Custom Sizes

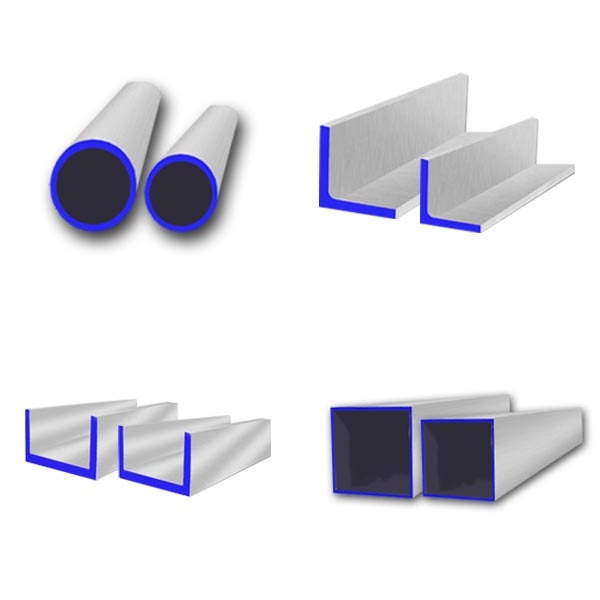

Available as angles, channels, pipes, and tubes. Angle sizes include 3/4"×3/4" to 1-1/2"×1-1/2" with thicknesses from 1/8" to 3/16". Other shapes available in standard mill sizes.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed 6063 Aluminum? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 1.282 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 1.110 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |