Cold Rolled Steel

About Cold Rolled Steel

Cold rolled steel provides a superior surface finish, tight dimensional tolerances, and increased strength over hot rolled products. Typically conforming to ASTM A108 for bar stock, it is ideal for precision parts, shafts, and decorative applications. In-stock in Los Angeles.

Quick Facts

- Material: Cold Rolled Steel (Typically 1018 Grade)

- ASTM Standard: A108 (for bar products)

- Temper/Condition: Cold Finished

- Available Sizes: All-thread rod from 1/4" to 5/8"; various bar and sheet sizes

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

Cold Rolled Steel (CRS) is a highly versatile and widely used material known for its exceptional surface quality and dimensional accuracy. The cold rolling process, which occurs below the steel's recrystallization temperature, increases its yield strength and hardness. This results in a product with a smooth, often slightly oily finish that is free of the scale found on hot rolled steel. Its tight tolerances reduce the need for secondary surface finishing, making it a cost-effective choice for parts requiring precision and a clean appearance.

The most common grade is 1018, a low-carbon steel that offers an excellent balance of toughness, strength, and ductility. This grade is easy to machine, fabricate, and weld, though welding can affect the material's precise dimensions in the heat-affected zone. Its predictable mechanical properties and superior finish make it a default material for manufacturers producing high-volume machined components, custom fixtures, consumer product casings, and parts where aesthetics and precision are paramount. It must be painted or plated to prevent rust.

Technical Specifications

Mechanical Properties (Typical for 1018 Grade)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 63,800 | PSI |

| Yield Strength | 53,700 | PSI |

| Elongation | 15 | % |

| Hardness | 126 | HB |

Applicable Standards

- ASTM A108: Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished

Common Applications

- Machinery & Automation: Shafts, spindles, gears, and mounting blocks - due to excellent machinability and dimensional stability.

- Automotive: Brackets, linkages, and non-critical engine components - for its reliable strength and formability.

- Tooling & Fixtures: Jigs, fixtures, and die sets - because it can be machined to precise, repeatable dimensions.

- Construction & Architecture: Threaded rods, fasteners, and decorative interior elements - where a smooth, paint-ready surface is required.

- Furniture Manufacturing: Frames, legs, and custom hardware - for its clean appearance and strength.

- Consumer Appliances: Enclosures, support frames, and internal components - requiring a consistent, high-quality finish.

- General Fabrication: Base plates, precision shims, and custom brackets - as an all-purpose material for high-quality work.

Working with Cold Rolled Steel

Machining

Cold rolled 1018 steel has excellent machinability, rated at 70% of 1212 steel. Its consistent hardness and smooth surface allow for fine finishes and high machining speeds. Use of a quality cutting fluid is recommended to prolong tool life and improve surface finish.

Welding

1018 steel is readily weldable using common methods including MIG, TIG, and stick welding. Pre-heating is not required for thin sections. For precision assemblies, be aware that the heat-affected zone will lose the temper and dimensional accuracy gained from the cold rolling process.

Finishing

The smooth, clean surface of cold rolled steel is an ideal base for painting, powder coating, and plating such as zinc or chrome. It must be coated to prevent corrosion, as it has no natural resistance to rust.

Grades Comparison

| Grade | Tensile (PSI) | Yield (PSI) | Best For |

|---|---|---|---|

| 1018 Cold Rolled | 63,800 | 53,700 | Precision parts, smooth finish |

| A36 Hot Rolled | 58,000-80,000 | 36,000 | Structural frames, general fab |

| 1045 Medium Carbon | 82,000 | 45,000 | Higher strength parts, gears |

| 4140 Alloy Steel | 95,000 | 60,000 | High-stress shafts, bolts |

Frequently Asked Questions

Q: What is the main difference between cold rolled and hot rolled steel?

A: Cold rolled steel is processed at room temperature after hot rolling. This increases its strength by up to 20%, creates a smoother surface finish, and holds much tighter dimensional tolerances. Hot rolled has a rough, scaly finish and is used where precision is less critical.

Q: Does cold rolled steel rust?

A: Yes, cold rolled steel is a carbon steel and will rust quickly if exposed to moisture. It must be protected with paint, oil, powder coating, or plating for any application where it might get damp.

Q: When should I choose cold rolled steel over A36 hot rolled?

A: Choose cold rolled steel when your project requires a superior surface finish, tight dimensional accuracy, and higher yield strength. It is ideal for machined parts where aesthetics or precision are key. A36 is better for structural applications where finish and tolerance are less critical.

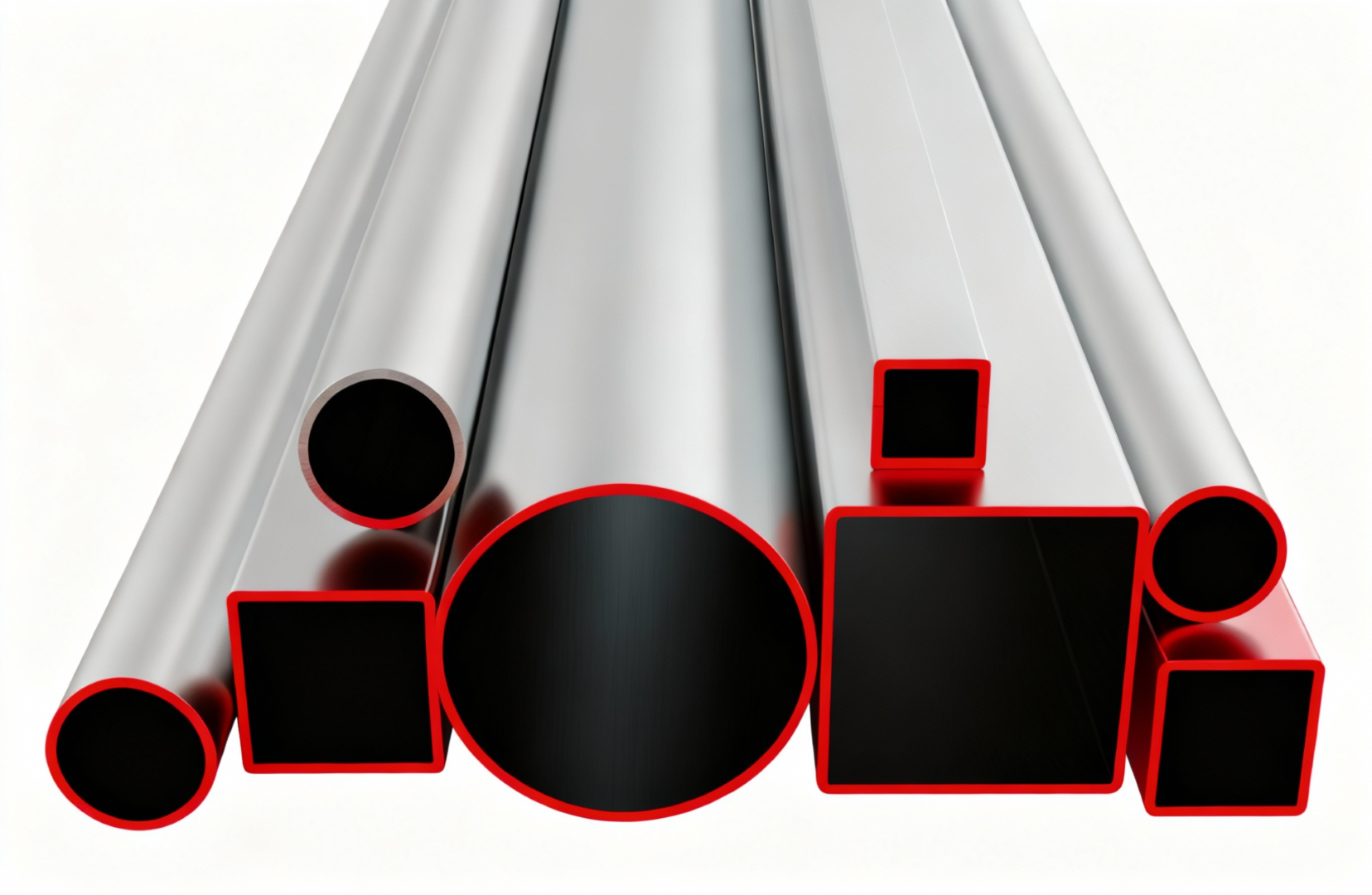

Stock & Custom Sizes

Available in a range of shapes including sheet, round bar, flat bar, and square bar. Common bar stock is available in diameters from 1/4" to 6", while standard sheet sizes include 4×8 ft and 4×10 ft. All-thread rod in stock from 1/4" to 5/8" diameter.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed Cold Rolled Steel? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 9.397 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 5.105 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 6.375 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 5.100 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |