6063 Aluminum Channels

About 6063 Aluminum Channels

6063 aluminum channel features excellent surface finish, high corrosion resistance, and good formability. Conforms to ASTM B308. Ideal for architectural trim and custom extrusions. In-stock Los Angeles with custom cutting available.

Quick Facts

- Material: 6063-T5 Aluminum

- ASTM Standard: B308

- Temper/Condition: T5 (Artificially aged)

- Available Sizes: Heights from 1/2" to 4"

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

6063 aluminum, often called the "architectural alloy," is a medium-strength material known for its superior surface finish and high resistance to corrosion. Alloyed primarily with magnesium and silicon, it offers excellent extrudability, allowing for complex shapes and fine details. Its properties make it a primary choice for applications where aesthetic appearance is as important as structural integrity, particularly for components that will be anodized to create a durable, decorative finish.

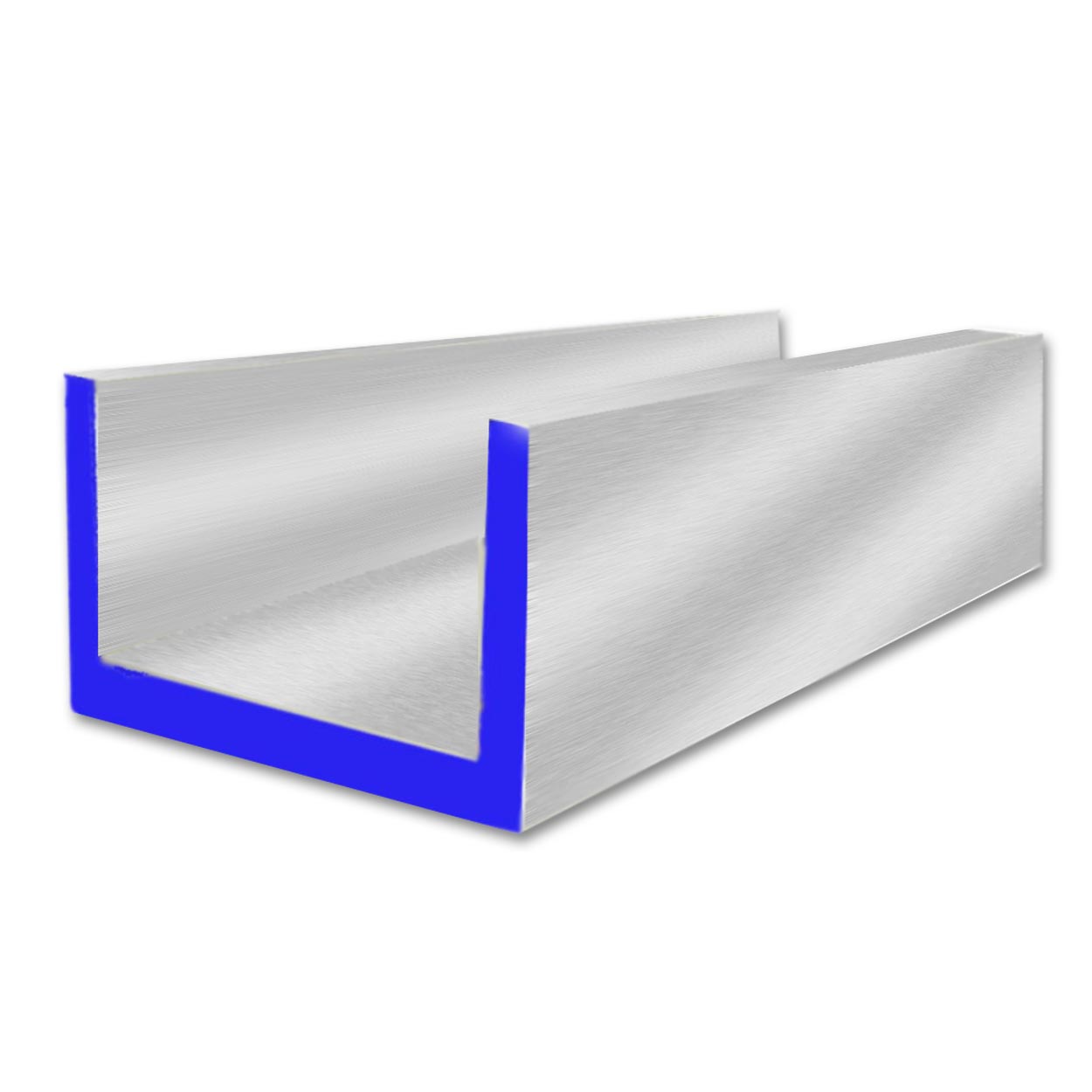

The channel form, with its C-shaped or U-shaped profile, provides versatile structural support for framing, tracks, and edging. In 6063 alloy, these channels are less suited for high-stress structural loads compared to 6061, but excel as components in window and door frames, railing systems, and furniture. The combination of the channel shape and 6063's properties results in a lightweight, corrosion-resistant, and visually appealing building material for various applications.

Technical Specifications

Mechanical Properties (6063-T5)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 27,000 | PSI |

| Yield Strength | 21,000 | PSI |

| Elongation | 12 | % |

| Hardness | 60 | HB |

Applicable Standards

- ASTM B308: Standard Specification for Aluminum-Alloy Standard Structural Profiles

Common Applications

- Architectural & Building: Window frames, door frames, and storefronts due to its excellent finish.

- Railing Systems: Handrails, guardrails, and balusters because of its corrosion resistance.

- Furniture Manufacturing: Legs, frames, and supports for modern furniture design.

- Enclosures & Housings: Casings for electronic equipment and custom project boxes.

- Trim & Molding: Decorative trim, wall panel joints, and protective corner guards.

- Signage & Displays: Lightweight frames for signs and exhibit structures.

- Solar Panel Framing: Mounting rails and support structures that resist weather exposure.

- Clean Rooms: Framing for walls and ceilings where a non-corrosive, clean finish is required.

Working with 6063 Aluminum Channels

Machining

6063 aluminum has fair machinability. Being softer than 6061, it can produce gummy chips. The use of sharp tooling, high speeds, and proper lubrication is recommended for a clean cut and to prevent material buildup on the tool.

Welding

This alloy exhibits excellent weldability using common methods like TIG (GTAW) and MIG (GMAW). 4043 filler wire is a common choice. The heat-affected zone will experience a reduction in strength from its original T5 temper, which should be considered in design.

Finishing

6063 is the premier choice for finishing. It is ideal for anodizing, which creates a hard, corrosion-resistant, and decorative surface in clear or colored finishes. It is also well-suited for powder coating and painting for enhanced durability and custom aesthetics.

Related Products

For applications requiring a similar profile but higher structural strength, consider 6061 Aluminum Channels. Bobco Metals also stocks 6063 alloy in other useful forms, including Angles and Square Tubes, which are also ideal for architectural and finishing projects.

Frequently Asked Questions

Q: What is the main difference between 6063 and 6061 aluminum channel?

A: 6063 has lower strength (27,000 PSI tensile vs. 6061's 45,000 PSI) but a superior surface finish, making it ideal for architectural and decorative applications where appearance is key. 6061 is preferred for structural applications requiring higher strength.

Q: Is 6063 aluminum channel suitable for outdoor use?

A: Yes, 6063 has excellent corrosion resistance, especially when anodized or powder-coated. This makes it a great choice for outdoor architectural elements like window frames, railings, and trim that are exposed to the elements.

Q: Can I bend 6063 aluminum channel?

A: Yes, 6063 aluminum has good formability and can be bent, though the minimum bend radius depends on wall thickness and profile. The T5 temper provides a good balance of strength and formability for most applications.

Stock & Custom Sizes

Available heights from 1/2" to 4". Flange widths and web thicknesses vary by profile. Standard lengths: 20 ft. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed 6063 Aluminum Channels? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 0.551 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |