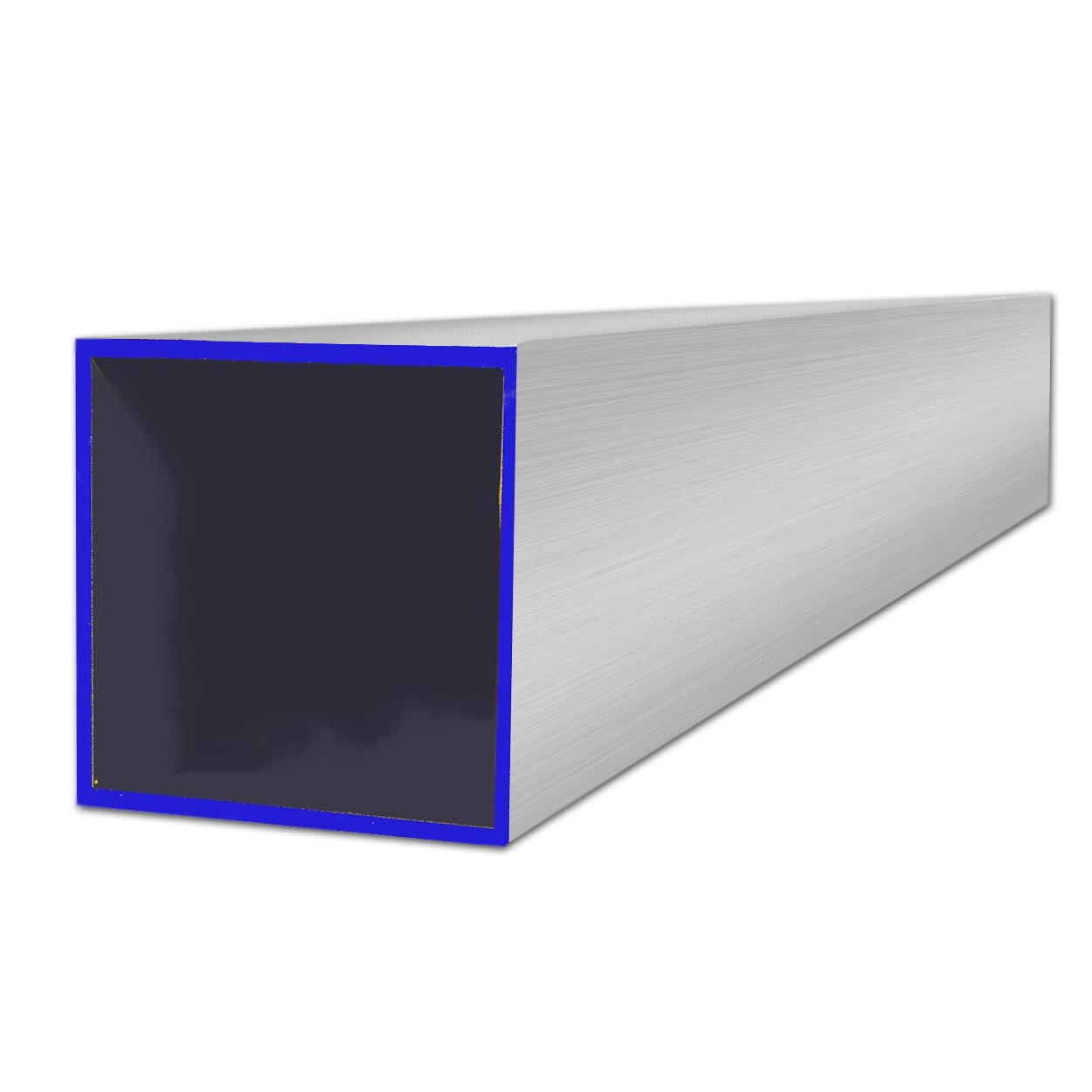

6061 Aluminum Square Tubes

About 6061 Aluminum Square Tubes

6061-T6 aluminum square tube provides an excellent strength-to-weight ratio, good machinability, and weldability. Conforms to ASTM B221. Used for structural frames, railings, and custom fabrications. Custom cutting available.

Quick Facts

- Material: 6061-T6 Aluminum

- ASTM Standard: B221

- Temper/Condition: T6 (Solution heat-treated, artificially aged)

- Available Sizes: 3/4" x 0.125" to 2" x 0.125"

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

6061 aluminum square tube is a versatile extruded product made from an alloy of magnesium and silicon. The T6 temper indicates it has been solution heat-treated and artificially aged, a process that significantly increases its strength and hardness. This combination results in a material with an exceptional strength-to-weight ratio, making it a reliable choice for applications where both durability and minimal weight are critical design factors.

A key advantage of 6061-T6 is its excellent fabrication characteristics. It can be easily welded using common methods like TIG or MIG, and it offers good machinability for creating precise components. Its smooth surface is suitable for anodizing, painting, or powder coating, providing enhanced corrosion protection and aesthetic appeal. These properties make it a staple for structural components, machine guards, railings, and display fixtures.

Technical Specifications

Mechanical Properties

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 45,000 | PSI |

| Yield Strength | 40,000 | PSI |

| Elongation | 12 | % |

| Hardness | 95 | HB |

Applicable Standards

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

Common Applications

- Structural Framing: Support trusses, machine frames, and workstations - Excellent strength-to-weight ratio.

- Architectural Fabrication: Window frames, door frames, and railing systems - High corrosion resistance and finishability.

- Automotive & Transportation: Chassis components, roof racks, and trailer frames - Lightweight and strong.

- Marine Applications: Boat railings, T-tops, and marine hardware - Good corrosion resistance in saltwater environments.

- Machinery & Automation: Robotic arms, conveyor frames, and protective guarding - Good machinability for custom fittings.

- Furniture & Displays: Retail displays, exhibit booths, and modern furniture frames - Lightweight and aesthetically pleasing when finished.

- DIY & Hobbyist Projects: Custom racks, shelving, and project enclosures - Easy to cut, drill, and assemble.

Working with 6061 Aluminum Square Tubes

Machining

6061-T6 aluminum has good machinability. It produces consistent chips and can be cut at high speeds. Use of a coolant or lubricant is recommended to prevent gumming and achieve a smooth surface finish. Carbide tooling is effective for milling, turning, and drilling operations.

Welding

This alloy offers excellent weldability using TIG (GTAW) or MIG (GMAW) welding processes with 4043 or 5356 filler wire. The heat-affected zone (HAZ) will experience a reduction in strength, which may require post-weld heat treatment for critical structural applications to restore the T6 temper.

Finishing

The surface of 6061 aluminum is well-suited for a variety of finishes. It can be anodized for increased surface hardness and corrosion resistance, powder coated for color and durability, or polished for a bright, reflective appearance. A standard mill finish is also common.

Related Products

Frequently Asked Questions

Q: What is the difference between 6061-T6 and 6063-T5 square tube?

A: 6061-T6 has higher strength (45,000 PSI tensile) and is better for structural applications. 6063-T5 has lower strength (27,000 PSI tensile) but a better surface finish and is often preferred for architectural applications like window frames and trim where strength is less critical.

Q: Can I bend 6061-T6 square tube?

A: Bending 6061-T6 can be challenging due to its hardness and may lead to cracking, especially with tight radii. For applications requiring significant forming, it's better to bend the material in its annealed ('O' temper) state and then heat-treat it to the T6 condition.

Q: Is 6061 aluminum square tube magnetic?

A: No, like all aluminum alloys, 6061 is non-magnetic. This property is useful in applications where magnetic interference must be avoided, such as in certain electronic enclosures or scientific instruments.

Stock & Custom Sizes

Available sizes: 3/4" x 3/4" to 2" x 2". Wall thickness: 0.125". Standard lengths: 20 ft. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed 6061 Aluminum Square Tubes? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 0.373 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size | ||

| 0.674 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |