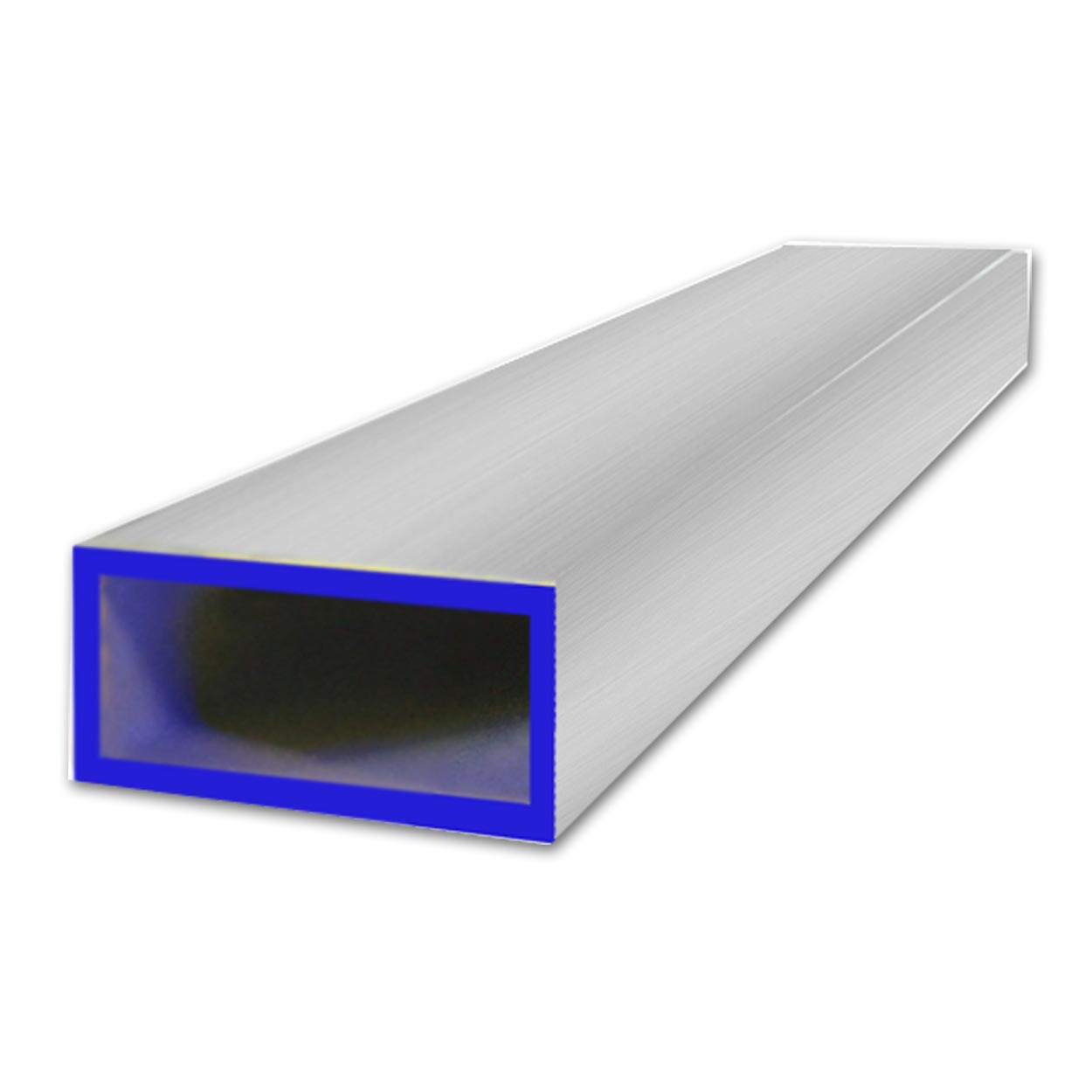

6061 Aluminum Rectangular Tubes

About 6061 Aluminum Rectangular Tubes

6061-T6 aluminum rectangular tube combines high strength, excellent weldability, and corrosion resistance. Conforms to ASTM B221. Used for structural frames and machine enclosures. Custom cutting available.

Quick Facts

- Material: 6061-T6 Aluminum

- ASTM Standard: B221

- Temper: T6 (Solution heat-treated, artificially aged)

- Available Sizes: 2" x 1" with 0.120" wall

- Location: Los Angeles warehouse

- Services: Custom size, same-day pickup

Overview

6061 aluminum is a precipitation-hardened alloy containing magnesium and silicon as its primary alloying elements. In the T6 temper, it is solution heat-treated and artificially aged to achieve high strength properties, making it one of the most versatile aluminum grades. Its excellent corrosion resistance, weldability, and good machinability allow it to be used in a wide range of demanding applications where both performance and fabrication ease are required.

The rectangular tube form provides significant structural advantages, offering high torsional rigidity and bending strength, especially along its major axis. This hollow shape delivers an exceptional strength-to-weight ratio, making it ideal for frameworks, supports, and enclosures. The extrusion process ensures tight dimensional tolerances and a smooth surface finish, suitable for both functional and aesthetic applications, from machinery guards to architectural trim that requires sharp, defined lines.

Technical Specifications

Mechanical Properties (6061-T6)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 45,000 | PSI |

| Yield Strength | 40,000 | PSI |

| Elongation | 12 | % |

| Hardness | 95 | HB |

| Shear Strength | 30,000 | PSI |

Applicable Standards

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

Common Applications

- Structural & Framing: Machine frames, safety guards, and support trusses - High strength and light weight.

- Automotive: Custom chassis components, roof racks, and running boards - Good strength-to-weight ratio.

- Architectural: Window frames, door frames, and decorative storefronts - Excellent corrosion resistance and finish.

- Marine: Boat railings, T-tops, and structural supports - Resists corrosion in marine environments.

- Fabrication: Workbenches, shelving units, and custom display fixtures - Easy to weld and machine.

- Aerospace: Non-critical aircraft components and ground support equipment - Lightweight strength.

- Electronics: Equipment enclosures and rack-mount frames - Good thermal conductivity and machinability.

Working with 6061 Aluminum Rectangular Tubes

Machining

6061-T6 aluminum has good machinability. It produces consistent chips and can be machined to tight tolerances using standard high-speed steel or carbide tooling. Use of cutting fluid is recommended to prevent chip welding and improve surface finish.

Welding

This alloy offers excellent weldability using common methods like TIG (GTAW) and MIG (GMAW). A 4043 or 5356 filler rod is typically used. The heat-affected zone will experience a reduction in strength, which may require post-weld heat treatment for critical applications.

Finishing

The material's surface is suitable for various finishes, including anodizing for enhanced corrosion and wear resistance, powder coating for color, or polishing for a decorative appearance. The mill finish is smooth and uniform.

Related Products

Frequently Asked Questions

Q: What is the difference between 6061 and 6063 aluminum tube?

A: 6061-T6 has higher strength (40,000 PSI yield) and is better for structural applications. 6063-T5 has lower strength (21,000 PSI yield) but a better surface finish and is typically used for architectural trim where strength is less critical.

Q: Can I use 6061 rectangular tube for outdoor projects?

A: Yes, 6061 aluminum has excellent corrosion resistance, making it well-suited for outdoor use. For enhanced protection, especially in coastal or harsh environments, anodizing or powder coating the surface is recommended.

Q: Is rectangular tube stronger than round tube of the same weight?

A: It depends on the loading direction. Rectangular tubing has higher bending stiffness along its taller axis, making it more resistant to bending forces in that direction compared to a round tube of equivalent weight.

Stock & Custom Sizes

Available sizes: 2" × 1". Wall thicknesses: 0.120". Standard lengths: 20 ft. Custom size available.

Same-day cutting and Los Angeles pickup available.

View Sizes & PricingNeed 6061 Aluminum Rectangular Tubes? Contact Bobco Metals for availability and Los Angeles pickup.

Request a Quote Ask an Expert| Item Size & Description | Weight (lbs.)/Ft | Click! Arrow to Select Size | Qty | Price | Actions |

|---|---|---|---|---|---|

| 0.840 |

Choose from predefined sizes or select custom size for manual entry |

Enter quantity between 1 and 999 | Select a Size |